What are we doing right now to reduce the environmental impact of our ceramics business?

Recovering heat from the kilns to heat the production departments and run the dryers.

A closed water system with full reuse and no water discharge.

Making use of ceramic waste by reintegrating it as a by-product in the supply chain.

Optimising energy consumption using efficient systems.

Using certified raw materials with up to 33% recycled content in our production.

Selecting suppliers using sustainability criteria to extend responsibility across the supply chain.

Managing

energy resources

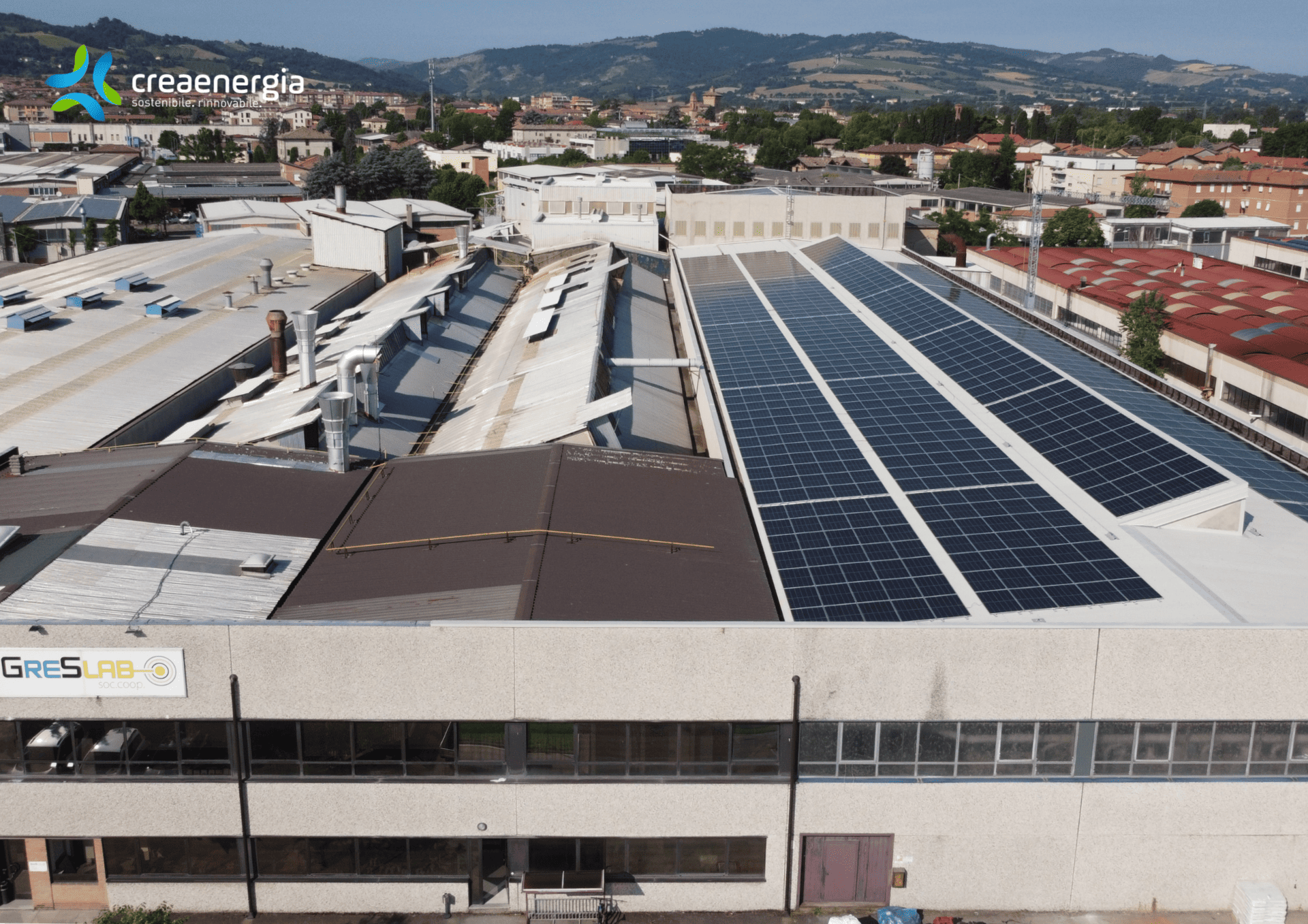

- A 540 kW photovoltaic plant, to increase renewable energy use.

- Highly energy efficient heating systems

- Digital monitoring of consumption to prevent energy waste.

Water management: a closed system with no waste

Water is a key resource in ceramic processes. As such, Greslab has put a circular management system in place to ensure full recovery of the process waters.

Waste management: reduction and recovery

Production waste is a resource for the entire production supply chain.

- 97% of total waste is sent for recovery

- Use of certified raw materials with up to 33% recycled content.

- Unfired and fired waste reintroduced to the production cycle using powder suppliers

- System for filtering and compacting grinding dust, to reduce its dispersal and facilitate its recovery.

Carbon Footprint: monitoring and reduction of emissions

Our commitment to the environment translates into active management of our Carbon Footprint, with strategies aimed at reducing the impact throughout the supply chain.

Managing direct emissions from fuel, gas and in-house logistics

Optimisation of electricity consumption, 12% reduction in energy-related emissions

Optimisation of electricity consumption, 12% reduction in energy-related emissions